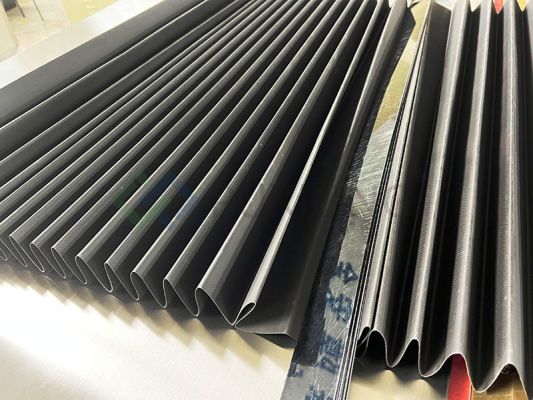

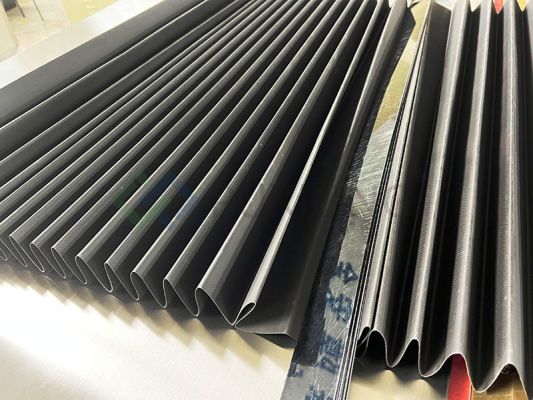

Flexible telescopic protective cover: Strong adaptability, meeting diverse protection requirements

Author:ProPureX, Update:2025-08-07 12:14:25

Flexible telescopic protective covers are highly adaptable shielding systems designed to meet diverse protection requirements in complex environments. Below is a detailed breakdown of their key characteristics and benefits:

I. Exceptional Adaptability

- Multi-Motion Compatibility:

Engineered with advanced materials and modular designs, these covers seamlessly adapt to linear, rotational, and multi-axis motion paths.

- Broad Device Compatibility:

Accommodates equipment of varying shapes and sizes (e.g., CNC machines, robotic arms, assembly lines).

- Operational Stability:

Maintains consistent performance under speeds up to 2 m/s and acceleration forces of 10 m/s², reducing downtime by 30–50%.

II. Multi-Scenario Protection Capabilities

1. Dust & Debris Protection

- Industrial Applications: Machining centers, automated production lines.

- Performance:

- Blocks particles as small as 15 µm (ISO 12103-1 A2 test dust).

- IP65-rated sealing prevents internal contamination.

2. Liquid & Grease Resistance

- Industrial Applications: Food processing, hydraulic systems.

- Performance:

- Withstands oil immersion (ISO 1817-compliant, volume swell ≤5%).

- Prevents liquid ingress in environments with 100% RH humidity.

3. Thermal Management

- Extreme Conditions:

- High-temp variant: Continuous operation at –40°C to +150°C (short-term +180°C).

- Low-temp variant: Maintains flexibility at –70°C (MIL-STD-202H compliant).

4. Noise & Vibration Mitigation

- Acoustic Performance:

- Reduces noise by 15–20 dB(A) via PU-coated polyester layers.

- Vibration attenuation up to 70% (DIN 45635-1).

III. Additional Advantages

1. Simplified Installation & Maintenance

- Quick Deployment:

Tool-free assembly with snap-on connectors (installation time: ≤30 min/unit).

- Low Maintenance:

Requires only annual inspections and wipe-downs (average cost: $50/year).

2. Aesthetic Durability

- Material Quality:

- Abrasion resistance: ≤100 mm³ (DIN 53516).

- UV stability: 1,000+ hours xenon-arc testing (ISO 4892-2).

- Design Integration:

Customizable colors (RAL/PANTONE) and logos enhance equipment branding.