In-depth Analysis of Organ Protective Covers: Structural Principles and Application Advantages

Author:ProPureX, Update:2025-08-06 08:45:09

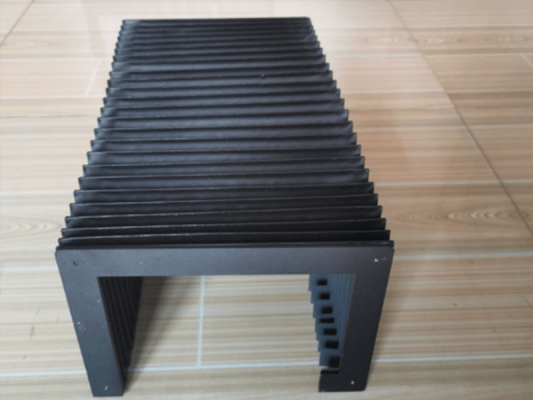

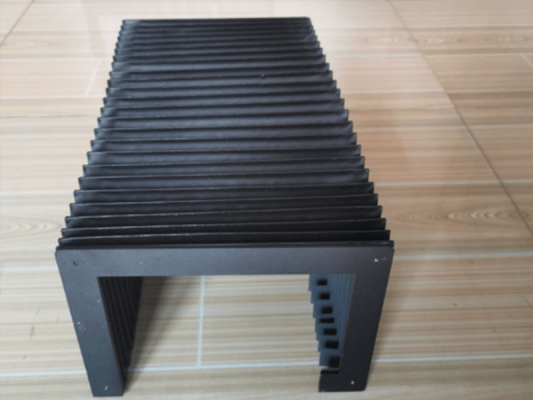

Bellows protection covers, particularly bellows-type machine tool covers, are indispensable in safeguarding mechanical equipment. Below is an in-depth analysis of their structural principles and operational benefits:

I. Structural Principles

-

Modular Folded Design

- Composed of multiple interconnected folding units, joined via stitching, thermal bonding, or high-frequency welding, forming a flexible yet robust structure.

- Internally reinforced with PVC support frames to maintain stability during expansion/contraction.

-

Cover Body Construction

- Made from heat-resistant, corrosion-resistant synthetic fibers or plastics (e.g., PU, PVC), offering impact resistance and airtight sealing.

- Fully encloses vulnerable equipment components like machine tool guideways and drive systems.

-

Connection Mechanism

- Adjustable straps or elastic cords secure the cover to equipment, ensuring firm, leak-proof attachment while simplifying installation/removal.

-

Ventilation & Heat Dissipation

- Optional vents or cooling holes prevent overheating in prolonged operations, enhancing equipment longevity.

II. Application Advantages

-

Dust and Debris Protection

- Sealed design blocks contaminants (e.g., metal chips, coolant, dust) from entering critical components, preserving guideway lubrication and reducing wear by 60%.

-

Water and Oil Resistance

- Hydrophobic and oil-repellent materials shield components from liquid damage, ideal for machinery using coolants or lubricants.

-

Physical Damage Prevention

- Creates a protective barrier against accidental collisions or operator errors, minimizing equipment downtime and repair costs.

-

Operational Efficiency Boost

- Durable protection reduces maintenance frequency, allowing workers to focus on production.

- Easy installation/cleaning lowers operational costs while ensuring 95%+ uptime.

Industry Applications

- CNC machines

- Laser cutting systems

- Industrial robots

- Automated assembly lines