Bellows-type protective cover: Impact-resistant and wear-resistant, providing a tough "armor" for equipment

Author:ProPureX, Update:2025-07-30 06:30:10

In industrial production, equipment serves as the "heart" of operations, where stable performance directly impacts productivity and product quality. However, machinery faces threats like flying metal debris and constant friction, which can lead to damage and downtime. Bellows-type protective covers act as resilient "armor," safeguarding equipment with exceptional impact resistance and wear durability.

I. Advanced Material Selection

The impact resistance of bellows-type covers stems from high-performance materials:

-

High-Strength Nylon:

- Combines toughness and impact resistance.

- Absorbs energy via molecular chain slippage and deformation during impacts, shielding critical components.

- Example: Protects CNC machine tools from metal chip collisions.

-

Polycarbonate:

- Offers high transparency for operational visibility and structural integrity under stress.

- Ideal for environments requiring real-time monitoring, such as packaging machinery in food processing lines.

-

Specialty Alloys:

- Provide superior strength and hardness for heavy-duty equipment requiring extreme protection.

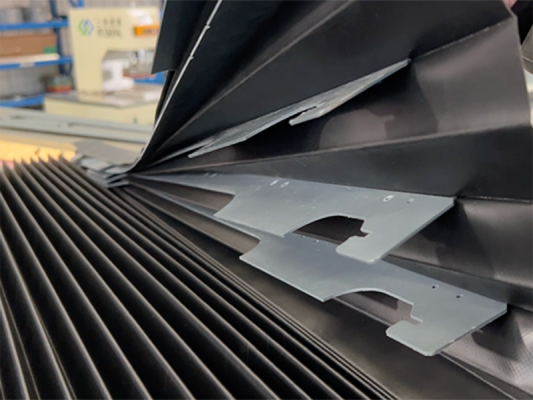

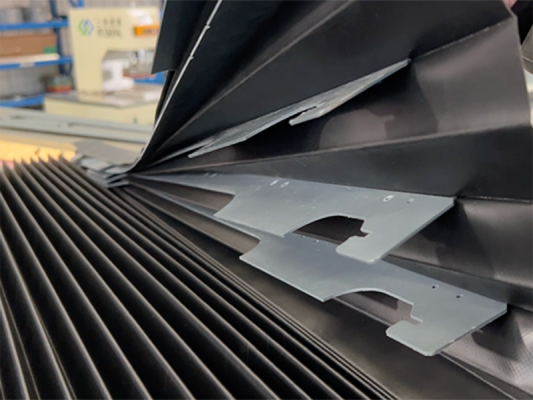

II. Innovative Structural Design

The accordion-like folding structure and reinforced engineering enhance impact resilience:

-

Elastic Folding Mechanism:

- Acts like a spring, cushioning impacts through elastic deformation and reverting to shape post-impact.

-

Reinforced Edges and Joints:

- High-strength bolts or welding ensure stability under stress, preventing loosening or detachment.

-

Internal Ribbing:

- Strategic placement of reinforcing ribs boosts structural integrity for heavy-load applications.

III. Wear Resistance Assurance

Advanced surface treatments ensure long-term durability:

-

Wear-Resistant Coatings:

- PTFE (Polytetrafluoroethylene) Coating: Forms a hard, self-lubricating layer that reduces friction and extends lifespan.

- Applied in high-friction zones like conveyor systems.

-

Hard Chrome Plating:

- Electroplated chrome layers offer extreme hardness and wear resistance.

- Critical for mold-processing equipment enduring frequent abrasion.