Special lead screw protective cover for CNC machine tools: Precise matching, enhancing processing accuracy

Author:ProPureX, Update:2025-07-18 11:20:35

Specialized Lead Screw Guard for CNC Machines

Through precision compatibility and multi-layer protection functions, this guard significantly improves machining accuracy. Its core advantages and application characteristics are as follows:

I. Core Functions & Machining Accuracy Enhancement Mechanisms

-

Contaminant Isolation & Accuracy Preservation

- The guard's physical barrier effectively isolates chips, coolant, and dust from invading screw surfaces, preventing transmission errors caused by friction coefficient changes.

- Example: During high-speed cutting, chip accumulation may increase screw surface wear by 30%, while the guard reduces this risk by >90%.

- Enhanced sealing minimizes coolant infiltration that dilutes screw lubricants, maintaining stable friction characteristics to ensure repeatable positioning accuracy of feed systems.

-

Dynamic Stability Enhancement

- Flexible materials (nylon fabric, rubber-coated fabric) enable synchronous telescoping with screw movement, eliminating vibration from rigid collisions.

- Example: In five-axis machining, the guard's dynamic tracking limits screw vibration to ±0.01mm, dramatically improving contouring precision.

- Wire-reinforced structures maintain shape stability during long extensions, preventing motion interference from guard sagging.

II. Material & Structural Compatibility Analysis

-

Material Selection

- Nylon: Lightweight (1.14g/cm³ density), wear-resistant (50-80MPa tensile strength), ideal for high-speed machines.

- Rubber-Coated Fabric: Superior flexibility for complex trajectories, commonly used in multi-axis equipment.

- Steel-Reinforced: Embedded steel wire rings withstand -40°C to 110°C environments, suitable for heavy-duty cutting.

-

Structural Adaptability

- Telescopic Design: Adjustable length via folding/coiling for Z-axis vertical movement.

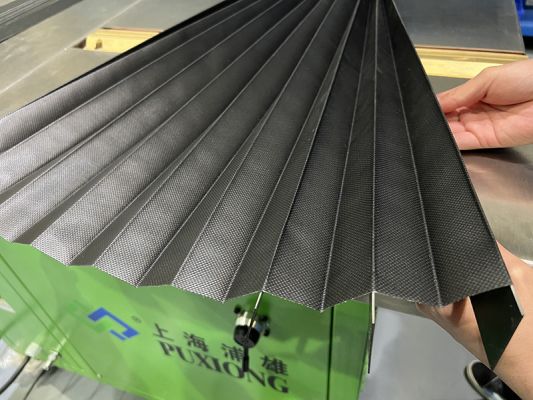

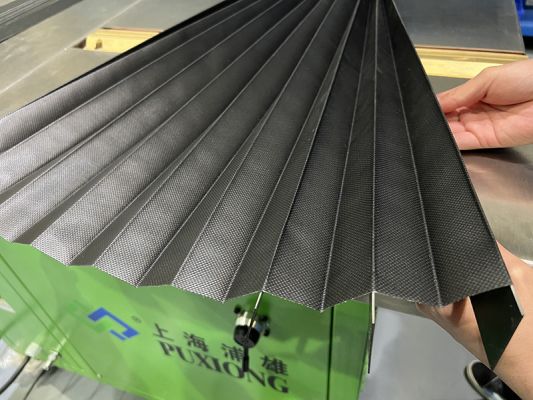

- Bellows Type: 10:1 compression ratio suits space-constrained X/Y axes.

- Spiral Steel Band: Stainless steel spiral winding (900°C resistant) for high-temperature environments.